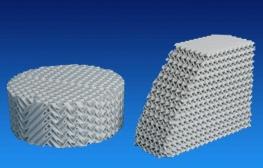

Ceramic Structured Packing

Ceramic structured packing is a kind of column shape and single layer corrugated packing, consisting of many moire pieces with the same geometric shape and parallel to each other. According to the different obliquity of corrugated sheet, this product is divided into X-style and Y-style, and X and Y correspond to the 300 and 450 respectively. Ceramic structured packing has a series of advantages, such as high efficiency, low pressure drop, great treatment, little liquid content, unremarkable amplifying effect and high elasticity in operation. With a unique structure, and excellent hydrophilic performance, the very thin liquid film can be formed in the surface of ceramic, and the flow of liquid film as well as oblique and flexural channel ensure the smooth airflow, and don’t impede it, making the efficiency of this product comparable with metallic corrugated packing. Yuanying makes the production of different specific surface area and flexible standard structured packing in terms of customer's demands.

Ceramic structured packing is not only widely used in coal gas washing tower, fertilizer heat gas saturation tower, naphthalene washing tower, ammonia washing tower, but also as the support for heat exchange machine , catalyst, and suit for a big tower rebuilding/revamp.

Main Performance

Type |

Specific area m2m3 |

Bulk density kg/m3 |

Void volume % |

Hydraulic diameter mm |

Liquid load m3/m2hr |

Max F-factor m/s(kg/m3)0.5 |

Pressure drop mmHg/m |

Theo.plate piece/m |

100X |

100 |

280 |

92 |

30 |

0.2-100 |

3.5 |

1.5 |

1 |

125Y |

125 |

320 |

90 |

28 |

0.2-100 |

3 |

1.5 |

1.8 |

125X |

125 |

300 |

90 |

28 |

0.2-100 |

3.2 |

1.8 |

1.5 |

150Y |

150 |

370 |

85 |

15 |

0.2-100 |

2.8 |

1.8 |

2 |

150X |

150 |

350 |

85 |

15 |

0.2-100 |

3 |

2 |

1.8 |

250Y |

250 |

420 |

80 |

12 |

0.2-100 |

2.6 |

2 |

2.5 |

250X |

250 |

400 |

80 |

12 |

0.2-100 |

2.8 |

2.5 |

2.3 |

350Y |

350 |

470 |

78 |

10 |

0.2-100 |

2.5 |

2.5 |

2.8 |

350X |

350 |

450 |

78 |

10 |

0.2-100 |

2.6 |

3 |

2.5 |

400Y |

400 |

500 |

75 |

8 |

0.2-100 |

2 |

3 |

3 |

400X |

400 |

480 |

75 |

8 |

0.2-100 |

2.2 |

4 |

2.8 |

450Y |

450 |

520 |

72 |

7 |

0.2-100 |

1.8 |

4 |

4 |

450X |

450 |

500 |

72 |

7 |

0.2-100 |

2 |

4.5 |

3.0-4.0 |

550Y |

550 |

620 |

74 |

6 |

0.18-100 |

1.4 |

5.5 |

5.0-6.0 |

550X |

550 |

620 |

74 |

6 |

0.18-100 |

1.4 |

5.5 |

5.0-6.0 |

700Y |

700 |

650 |

72 |

5 |

0.15-100 |

1.3 |

6 |

7 |

700X |

700 |

650 |

72 |

5 |

0.15-100 |

1.3 |

6 |

7 |

Physical Properties

Item |

Index |

Specific gravity g/cm3 |

2.5 |

Water absorption % |

≤0.5 |

Acid resistance % |

≥99.5 |

Max operating temp. ℃ |

800 |

Loss on ignition % |

≤5 |

Moh's hardness scale |

≥7 |

Crush strength Mpa |

≥130 |

Chemical Composition

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

Others |

≥72% |

≥23% |

≤0.5% |

≤1.0% |

≤1.0% |

2% |

Tolerance

Tower diameter φmm |

200 |

200-400 |

400-800 |

800-1200 |

1200-2000 |

2000-4000 |

4000-6000 |

>6000 |

X mm |

-10 |

-12 |

-15 |

-18 |

-20 |

-25 |

-28 |

-32 |

Y mm |

-5 |

-6 |

-8 |

-10 |

-12 |

-15 |

-18 |

-20 |

Typical Application

100X

The feature of high corrosion resistance makes it specially suitable for refinery of oil with high acid value, protecting naphthenic acid from corrosion. It is a good choice for desulfurization apparatus and towers.

250X, Y

Widely used in the process of separation for mineral brine lixiviant reactant mixture, rectification for organic acid solutions as well as absorption / desorption for vitriol medium.

350X, Y

Widely used in the acid dehydrator to reduce reflux, increase acetic acid and lower column operation temperature. Excellent separation performance for the process of high vacuum decompression , its ideal high temperature and corrosion resistant packing material for the glass, glass fibre reinforced plastic and enamel tower.

450X, Y

Widely used in absorption, desorption, separation of rectification for corrosion mixture, requiring the theoretical plate 4-5, economic loading range: F factor 1.5-2.

700 X

Specially designed for the high mass-transfer efficiency rectification towers, Yuanying suggest a support grid should be installed every 3 to 4 meters height of this structured packing. |